스프링호스

PVC Thunder Spring Hose

용도 Application

- 분말, 분체 등 다양한 원재료 이송용

- 음료, 주료 이송용

- 공작기계의 급유(윤활유, 절삭유) 배관

- 내·외압성 및 흡입이 요구되는 기계장치의 배관

- For Transfer of Diverse Raw Materials in Powder, Particle, etc. Form

- For Transfer of Drinks, Alcoholic Drinks, etc.

- (Lubricant, Cutting Oil, etc.) Refueling Pipes for Construction Machines

- Pipes of Machines for External or Internal Pressure-Resisting Quality and Suction

특징 Properties

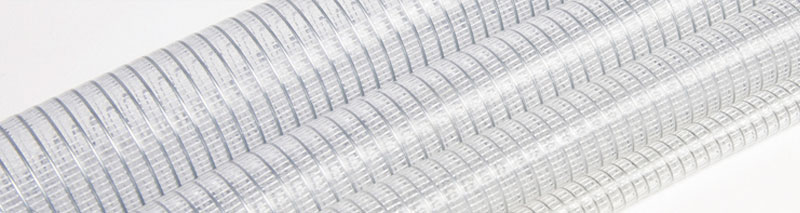

- 내·외면 사이에 특수강선 보강으로 유연성, 내·외압성이 높으며, 특수 강선을 통한 정전기방지

- 높은 투명성으로 분체 및 원료 이송상태 확인이 용이함

- 식품용 호스제품으로 물, 알코올, 초산류 제품에 사용이 가능한 제품

- 내한성, 내약품성이 우수

- Prevention of Electrostatic through Specially Strengthened Steel Wires Between Inside and Outside for Higher Flexibility and Internal and External Pressure Resistance

- Ease of Cheking the Transfer of Raw Materials and Powders with Hight Transpaerency

- Hoses for Liquid Foods Such as Water, Alcoho and Vinegar Containing Products

- Outstanding Resistance to Cold Weather and Drugs

썬더 스프링호스(A급) Thunder Spring Hose(Class A)

| 규격 |

내경(mm) |

외경(mm) |

상용압력(kgf/cm²) |

파열압력(kgf/cm²) |

포장단위(M) |

| (mm) |

(inch) |

| 8 |

5/16 |

8 |

13.5 |

8 |

25 |

100 |

| 9 |

3/8 |

9 |

15 |

8 |

25 |

100 |

| 10 |

13/32 |

10 |

16 |

7 |

20 |

100 |

| 12 |

1/2 |

12 |

18 |

6 |

20 |

100 |

| 15 |

5/8 |

15 |

22 |

6 |

20 |

100 |

| 19 |

3/4 |

19 |

26 |

5 |

15 |

50 |

| 25 |

1 |

25 |

33 |

5 |

15 |

50 |

| 32 |

1 1/4 |

32 |

41 |

4 |

13 |

40 |

| 38 |

1 1/2 |

38 |

48 |

4 |

12 |

40 |

| 50 |

2 |

50 |

62 |

3 |

10 |

40 |

| 65 |

2 1/2 |

65 |

79 |

3 |

10 |

20 |

| 75 |

3 |

75 |

90 |

3 |

10 |

20 |

※상기 사양외 특수사양 주문생산 가능

(Other Special Specifications-Customized Production Other than Products Above)

※허용공차 ±0.3~±1.0mm 입니다.

(Allowed Tolerance : ±0.3~±1.0mm)

HF 스프링호스(B급) HF Spring Hose(Class B)

| 규격 |

내경(mm) |

외경(mm) |

상용압력(kgf/cm²) |

파열압력(kgf/cm²) |

포장단위(M) |

| (mm) |

(inch) |

| 15 |

5/8 |

15 |

21 |

5 |

19 |

100 |

| 19 |

3/4 |

19 |

25 |

4 |

14 |

50 |

| 25 |

1 |

25 |

32 |

4 |

14 |

50 |

| 32 |

1 1/4 |

32 |

39 |

3 |

12 |

40 |

| 38 |

1 1/2 |

38 |

46 |

4 |

10 |

40 |

| 50 |

2 |

50 |

60 |

2 |

10 |

40 |

※상기 사양외 특수사양 주문생산 가능

(Other Special Specifications-Customized Production Other than Products Above)

※허용공차 ±0.3~±1.0mm 입니다.

(Allowed Tolerance : ±0.3~±1.0mm)

스프링 편사 호스

Braided Spring Hose

특징 Properties

- 직선 보강사로 사용압력이 스프링 호스보다 약 2배 높음

- 투명성을 요구하는 곳에 진공펌프 호스로 사용할 수 있음

- 내·외압력 및 장력이 매우 우수함

- 2x Higher Pressure than Spring Hoses with Reinforced Straight-Line Braid

- Can be used as Vacuum Pump Hose for Places where High Transparency is Required

- Excellent External and Internal Pressure Resistance and Tension

| 규격 |

내경(mm) |

외경(mm) |

상용압력(kgf/cm²) |

파열압력(kgf/cm²) |

포장단위(M) |

| (mm) |

(inch) |

| 25 |

1 |

25 |

33 |

10 |

40 |

50 |

| 32 |

1 1/4 |

32 |

41 |

8 |

30 |

40 |

| 38 |

1 1/2 |

38 |

48 |

8 |

30 |

40 |

| 50 |

2 |

50 |

62 |

6 |

25 |

40 |

※상기 사양외 특수사양 주문생산 가능

(Other Special Specifications-Customized Production Other than Products Above)

※허용공차 ±0.5~±1.0mm 입니다.

(Allowed Tolerance : ±0.5~±1.0mm)